Hazardous Materials Management in Building Repairs: Environmental Regulations in Canada

When undertaking building repairs or renovations, managing hazardous materials is a critical aspect that ensures both environmental protection and public health safety. In Canada, a variety of hazardous substances, such as asbestos, lead, and mercury, are commonly found in older buildings. The improper handling of these materials can lead to severe environmental contamination and health risks, making it essential to follow strict regulations during repairs and renovations. This article will explore the key environmental regulations governing hazardous materials management in building repairs in Canada and outline best practices to ensure compliance and safety.

The Importance of Hazardous Materials Management

Many older buildings across Canada contain materials that were once widely used in construction but are now known to pose health risks. These materials include asbestos in insulation and fireproofing, lead in paints and plumbing, and mercury in older lighting systems. If disturbed during repairs or renovations, these substances can release toxic particles into the air or contaminate soil and water, leading to serious health risks for workers and occupants.

Hazardous materials management is crucial to:

- Prevent environmental contamination: Improper disposal of hazardous materials can lead to soil and water contamination, affecting ecosystems and potentially entering the food chain.

- Protect worker and occupant health: Exposure to hazardous materials such as asbestos and lead can cause serious health conditions, including respiratory diseases, cancer, and developmental issues.

- Ensure compliance with environmental laws: Failing to properly manage hazardous materials can result in hefty fines and legal repercussions, as well as delays in project completion.

Common Hazardous Materials in Building Repairs

Before diving into the regulations, it’s essential to understand the common hazardous materials that are often encountered during building repairs and renovations in Canada.

1. Asbestos

Asbestos was widely used in building materials such as insulation, roofing, and floor tiles until its harmful effects became well-known. When disturbed, asbestos fibers can become airborne and, if inhaled, can cause serious respiratory illnesses, including asbestosis, mesothelioma, and lung cancer.

2. Lead

Lead was a common component of paint and plumbing systems in buildings constructed before the 1980s. Lead exposure, particularly in children, can cause developmental delays, cognitive impairments, and various other health issues.

3. Mercury

Mercury is often found in older thermostats, lighting systems (such as fluorescent bulbs), and electrical switches. If not handled properly during repairs, mercury can be released into the environment, where it can contaminate soil and water and pose serious health risks.

4. Polychlorinated Biphenyls (PCBs)

PCBs were used in electrical equipment, such as transformers and capacitors, until their production was banned in the late 1970s. These chemicals are highly toxic and persistent in the environment, posing significant risks to both human health and ecosystems.

Environmental Regulations Governing Hazardous Materials in Canada

Several federal, provincial, and municipal regulations govern the handling, removal, and disposal of hazardous materials during building repairs. These regulations are designed to minimize environmental risks and ensure the safe management of toxic substances.

1. Canadian Environmental Protection Act (CEPA)

The Canadian Environmental Protection Act (CEPA) is the cornerstone of environmental legislation in Canada. Under CEPA, the handling and disposal of hazardous materials, including asbestos, lead, mercury, and PCBs, are strictly regulated. CEPA establishes guidelines for identifying hazardous substances, proper removal techniques, and disposal requirements to prevent environmental contamination.

CEPA also enforces the Asbestos Products Regulations, which ban the import, sale, and use of asbestos in Canada. For repairs or renovations in buildings that contain asbestos, specific measures must be taken to safely remove and dispose of the material.

2. Workplace Hazardous Materials Information System (WHMIS)

The Workplace Hazardous Materials Information System (WHMIS) is a national system that ensures workers handling hazardous materials have the information and training needed to do so safely. WHMIS requires employers to provide proper labeling, safety data sheets (SDS), and worker education programs for any hazardous substances encountered during building repairs. WHMIS guidelines are particularly important for contractors and construction workers who may be exposed to hazardous materials during renovation projects.

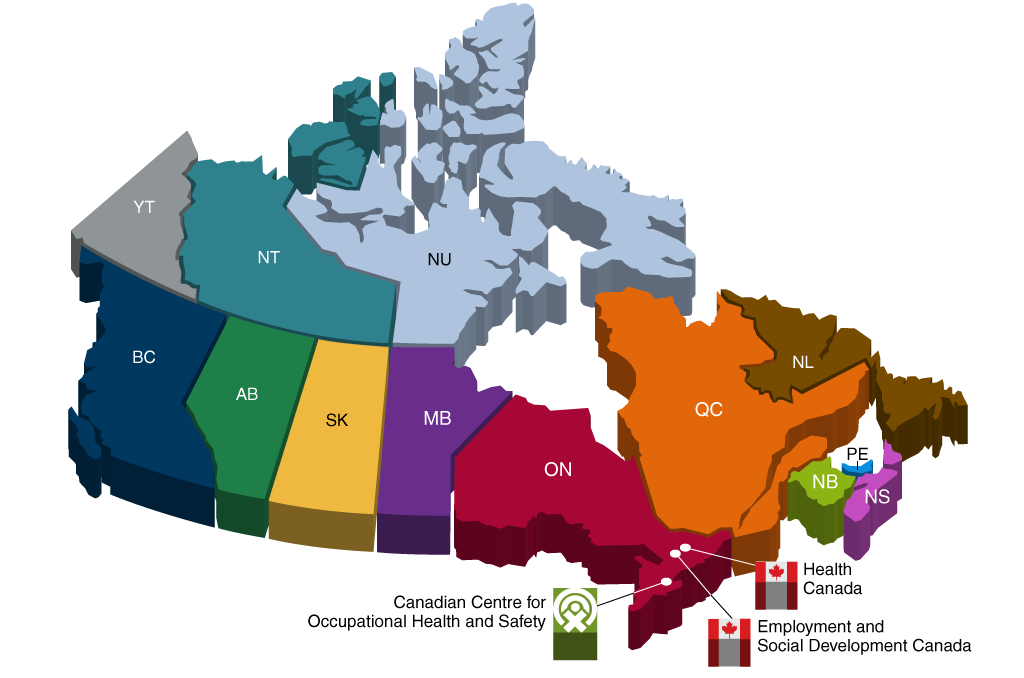

3. Provincial Regulations for Hazardous Materials

Each province in Canada has its own regulations for managing hazardous materials, often building on the federal guidelines provided by CEPA and WHMIS. These provincial regulations may cover more specific requirements for identifying, handling, and disposing of hazardous substances during building repairs.

For example:

- Ontario: Ontario’s Occupational Health and Safety Act (OHSA) includes stringent guidelines for the management of asbestos during building renovations. The act mandates that an asbestos survey must be conducted before any demolition or renovation project, and workers handling asbestos must follow strict safety protocols.

- British Columbia: BC’s Workers Compensation Act and Hazardous Waste Regulation include provisions for the safe removal and disposal of asbestos, lead, and other hazardous materials. The regulations also require building owners to hire certified contractors for hazardous materials removal and disposal.

4. Municipal By-laws

In addition to federal and provincial regulations, some municipalities have specific by-laws governing the removal and disposal of hazardous materials. These by-laws may require permits for hazardous material removal or mandate particular disposal methods for substances like asbestos or lead-based paint.

Best Practices for Managing Hazardous Materials During Building Repairs

Ensuring compliance with hazardous materials regulations requires careful planning, specialized knowledge, and adherence to best practices. Below are some key steps to safely manage hazardous materials during building repairs or renovations:

1. Conduct a Hazardous Materials Survey

Before starting any repair or renovation project, it’s essential to conduct a hazardous materials survey, especially in buildings constructed before the 1980s. This survey should identify any asbestos, lead, mercury, or other hazardous substances present in the building. The survey must be carried out by a certified environmental consultant or hazardous materials expert.

2. Hire Licensed Professionals for Hazardous Materials Removal

The removal of hazardous materials like asbestos, lead, and PCBs must be handled by licensed professionals who are trained in proper removal techniques. These professionals will ensure that the materials are safely contained, removed, and disposed of according to provincial and federal guidelines. Attempting to handle hazardous materials without proper certification can lead to severe health risks and legal liabilities.

3. Use Proper Containment and Ventilation

During the removal of hazardous materials, proper containment and ventilation are critical to prevent the spread of toxic substances. For example, when removing asbestos, the work area should be sealed off using plastic sheeting, and specialized ventilation systems should be employed to prevent airborne fibers from escaping.

4. Dispose of Hazardous Materials Safely

Once hazardous materials are removed, they must be disposed of at a certified hazardous waste disposal facility. Transporting hazardous waste is strictly regulated, and contractors must follow specific guidelines for packaging and labeling these materials. Failure to dispose of hazardous waste correctly can lead to significant fines and environmental damage.

5. Provide Worker Training and Protective Equipment

Workers involved in building repairs or renovations where hazardous materials are present must receive proper training on handling these substances. This training should include WHMIS instruction, the use of personal protective equipment (PPE), and emergency procedures in case of exposure. Employers are responsible for ensuring that workers are adequately protected and trained to manage hazardous materials safely.

6. Implement a Hazardous Materials Management Plan

For larger projects, a hazardous materials management plan should be developed to outline the steps for identifying, containing, removing, and disposing of hazardous materials. This plan should include clear communication protocols, worker training programs, and contingency plans in case of accidental exposure or spills.

Conclusion

Managing hazardous materials during building repairs is a complex but essential process to protect public health and the environment. In Canada, federal regulations like CEPA, provincial rules, and municipal by-laws provide a comprehensive framework for the safe handling, removal, and disposal of hazardous substances. By following best practices, such as conducting hazardous material surveys, hiring licensed professionals, and ensuring safe disposal, building owners and contractors can successfully navigate the regulatory landscape while minimizing environmental risks.